Page 100 - IS-Rayfast Catalogue - Issue 9, 2017

P. 100

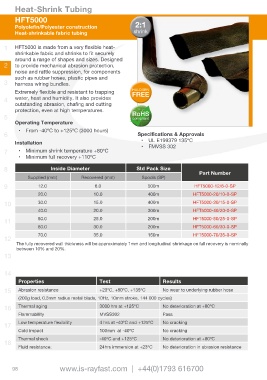

Heat-Shrink Tubing

HFT5000

Polyolefin/Polyester construction 2:1

Heat-shrinkable fabric tubing shrink

1 HFT5000 is made from a very flexible heat-

shrinkable fabric and shrinks to fit securely

around a range of shapes and sizes. Designed

2 to provide mechanical abrasion protection,

noise and rattle suppression, for components

such as rubber hoses, plastic pipes and

3 harness wiring bundles.

HALOGEN

Extremely flexible and resistant to trapping FREE

4 water, heat and humidity. It also provides

outstanding abrasion, chafing and cutting

protection, even at high temperatures. RoHS

5 compliant

Operating Temperature

• From -40ºC to +125ºC (3000 hours)

6 Specifications & Approvals

• UL E199379 135ºC

Installation

• FMVSS 302

7 • Minimum shrink temperature +80ºC

• Minimum full recovery +110ºC

8 Inside Diameter Std Pack Size

Part Number

Supplied (mm) Recovered (mm) Spools (SP)

9 12.0 6.0 500m HFT5000-12/6-0-SP

20.0 10.0 400m HFT5000-20/10-0-SP

10 30.0 15.0 400m HFT5000-30/15-0-SP

40.0 20.0 300m HFT5000-40/20-0-SP

50.0 25.0 200m HFT5000-50/25-0-SP

11

60.0 30.0 200m HFT5000-60/30-0-SP

70.0 35.0 150m HFT5000-70/35-0-SP

12

The fully recovered wall thickness will be approximately 1mm and longitudinal shrinkage on full recovery is nominally

between 10% and 20%.

13

14

Properties Test Results

15 Abrasion resistance +23ºC, +80ºC, +135ºC No wear to underlying rubber hose

(200g load, 0.3mm radius metal blade, 10Hz, 10mm stroke, 144 000 cycles)

16 Thermal aging 3000 hrs at +125ºC No deterioration at +80ºC

Flammability MVSS302 Pass

Low temperature flexibility 4 hrs at -40ºC and +125ºC No cracking

17

Cold impact 100mm at -40ºC No cracking

Thermal shock -40ºC and +125ºC No deterioration at +80ºC

18

Fluid resistance: 24hrs immersion at +23ºC No deterioration in abrasion resistance

98 www.is-rayfast.com | +44(0)1793 616700