Page 148 - IS-Rayfast Catalogue - Issue 9, 2017

P. 148

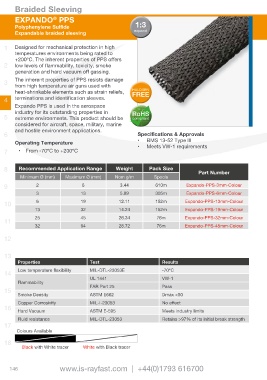

Braided Sleeving

®

EXPANDO PPS

Polyphenylene Sulfide 1:3

expand

Expandable braided sleeving

1 Designed for mechanical protection in high

temperatures environments being rated to

+200ºC. The inherent properties of PPS offers

2 low levels of flammability, toxicity, smoke

generation and hard vacuum off gassing.

The inherent properties of PPS resists damage

3

from high temperature air guns used with

HALOGEN

heat-shrinkable elements such as strain reliefs, FREE

4 terminations and identification sleeves.

Expando PPS is used in the aerospace

industry for its outstanding properties in RoHS

5 extreme environments. This product should be compliant

considered for aircraft, space, military, marine

and hostile environment applications.

6 Specifications & Approvals

• BMS 13-52 Type III

Operating Temperature

• Meets VW-1 requirements

7 • From -70ºC to +200ºC

8 Recommended Application Range Weight Pack Size

Part Number

Minimum Ø (mm) Maximum Ø (mm) Nom g/m Spools

9 2 6 3.44 610m Expando-PPS-3mm-Colour

3 13 5.89 305m Expando-PPS-6mm-Colour

6 19 12.11 152m Expando-PPS-13mm-Colour

10

13 32 14.24 152m Expando-PPS-19mm-Colour

25 45 26.34 76m Expando-PPS-32mm-Colour

11

32 64 28.72 76m Expando-PPS-45mm-Colour

12

13

Properties Test Results

Low temperature flexibility MIL-DTL-23053E -70ºC

14

UL 1441 VW-1

Flammability

FAR Part 25 Pass

15

Smoke Density ASTM E662 Dmax <50

Copper Corrosivity MIL-I-23053 No effect

16

Hard Vacuum ASTM E-595 Meets industry limits

Fluid resistance MIL-DTL-23053 Retains >97% of its initial break strength

17

Colours Available

18

Black with White tracer White with Black tracer

146 www.is-rayfast.com | +44(0)1793 616700