Page 415 - IS-Rayfast Catalogue - Issue 9, 2017

P. 415

Metal Braids

Power Shunts

Custom Solutions

Large Braid Connectors

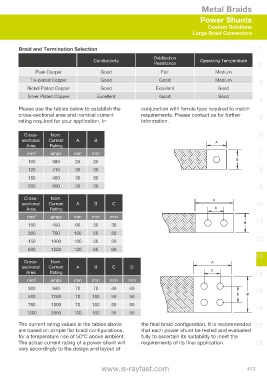

Braid and Termination Selection 1

Oxidisation

Conductivity Operating Temperature

Resistance

2

Plain Copper Good Fair Medium

Tin-plated Copper Good Good Medium

3

Nickel Plated Copper Good Excellent Good

Silver Plated Copper Excellent Good Good

4

Please use the tables below to establish the conjunction with ferrule type required to match

cross-sectional area and nominal current requirements. Please contact us for further 5

rating required for your application, in information.

Cross- Nom. 6

sectional Current A B

Area Rating

mm 2 amps mm mm 7

100 380 25 25

120 410 30 30 8

150 450 30 30

200 600 30 30 9

Cross- Nom.

sectional Current A B C 10

Area Rating

mm 2 amps mm mm mm

11

150 450 60 30 30

300 760 100 50 50

12

450 1000 100 50 50

600 1220 120 60 60

13

Cross- Nom.

sectional Current A B C D

Area Rating 14

mm 2 amps mm mm mm mm

300 940 70 70 40 40

15

500 1280 70 100 50 50

750 1500 70 100 50 50

16

1000 2000 100 100 50 50

The current rating values in the tables above the final braid configuration. It is recommended 17

are based on simple flat braid configurations, that each power shunt be tested and evaluated

for a temperature rise of 50ºC above ambient. fully to ascertain its suitability to meet the

The actual current rating of a power shunt will requirements of its final application. 18

vary accordingly to the design and layout of

www.is-rayfast.com 413