Page 227 - IS-Rayfast Catalogue - Issue 9, 2017

P. 227

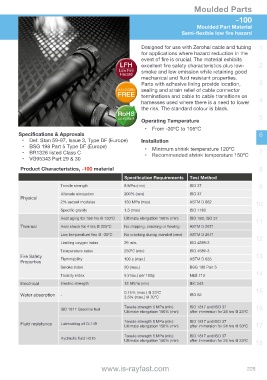

Moulded Parts

-100

Moulded Part Material

Semi-flexible low fire hazard

Designed for use with Zerohal cable and tubing 1

for applications where hazard reduction in the

LFH event of fire is crucial. The material exhibits 2

excellent fire safety characteristics plus low-

Low Fire smoke and low emission while retaining good

Hazard

mechanical and fluid resistant properties.

Parts with adhesive lining provide location, 3

HALOGEN

FREE sealing and strain relief of cable connector

terminations and cable to cable transitions on

4

harnesses used where there is a need to lower

RoHS the risk. The standard colour is black.

compliant 5

Operating Temperature

• From -30ºC to 105ºC

Specifications & Approvals 6

• Def. Stan 59-97, Issue 3, Type DF (Europe) Installation

• BSG 198 Part 5 Type DF (Europe) • Minimum shrink temperature 120ºC

• BR1326 listed Class C • Recommended shrink temperature 150ºC 7

• VG95343 Part 29 & 30

Product Characteristics, -100 material 8

Specification Requirements Test Method

Tensile strength 8 MPa (min) ISO 37 9

Ultimate elongation 200% (min) ISO 37

Physical

2% secant modulus 130 MPa (max) ASTM D 882

10

Specific gravity 1.5 (max) ISO 1183

Heat aging for 168 hrs @ 150ºC Ultimate elongation 150% (min) ISO 188, ISO 37

11

Thermal Heat shock for 4 hrs @ 225ºC No dripping, cracking or flowing ASTM D 2671

Low temperature flex @ -30ºC No cracking during mandrel bend ASTM D 2671

12

Limiting oxygen index 29 min. ISO 4589-2

Temperature index 250ºC (min) ISO 4589-3

Fire Safety Flammability 100 s (max.) ASTM D 635 13

Properties

Smoke index 20 (max.) BSG 198 Part 5

14

Toxicity index 5 )max.) per 100g NES 713

Electrical Electric strength 15 MV/m (min) IEC 243

15

0.75% (max.) @ 23ºC

Water absorption - ISO 62

3.5% (max.) @ 70ºC

Tensile strength 5 MPa (min) ISO 1817 and ISO 37

ISO 1817 Gasoline fuel 16

Ultimate elongation 150% (min) after immersion for 24 hrs @ 23ºC

Tensile strength 5 MPa (min) ISO 1817 and ISO 37

Fluid resistance Lubricating oil O-149

Ultimate elongation 150% (min) after immersion for 24 hrs @ 50ºC 17

Tensile strength 5 MPa (min) ISO 1817 and ISO 37

Hydraulic fluid H515

Ultimate elongation 150% (min) after immersion for 24 hrs @ 23ºC

18

www.is-rayfast.com 225