Page 225 - IS-Rayfast Catalogue - Issue 9, 2017

P. 225

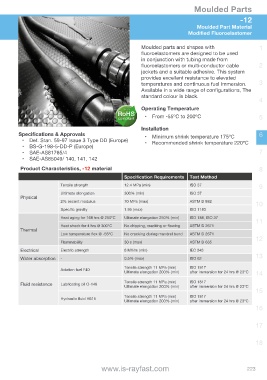

Moulded Parts

-12

Moulded Part Material

Modified Fluoroelastomer

Moulded parts and shapes with 1

fluoroelastomers are designed to be used

in conjunction with tubing made from

fluoroelastomers or multi-conductor cable 2

jackets and a suitable adhesive. This system

provides excellent resistance to elevated

temperatures and continuous fuel immersion. 3

Available in a wide range of configurations, The

standard colour is black.

4

RoHS Operating Temperature

compliant • From -55ºC to 200ºC 5

Installation

Specifications & Approvals • Minimum shrink temperature 175ºC 6

• Def. Stan. 59-97 Issue 3 Type DD (Europe)

• Recommended shrink temperature 220ºC

• BS-G-198-5-DD-P (Europe)

• SAE-AS81765/4 7

• SAE-AS85049/ 140, 141, 142

Product Characteristics, -12 material 8

Specification Requirements Test Method

Tensile strength 12.4 MPa (min) ISO 37

9

Ultimate elongation 300% (min) ISO 37

Physical

2% secant modulus 70 MPa (max) ASTM D 882

10

Specific gravity 1.95 (max) ISO 1183

Heat aging for 168 hrs @ 250ºC Ultimate elongation 250% (min) ISO 188, ISO 37

11

Heat shock for 4 hrs @ 300ºC No dripping, cracking or flowing ASTM D 2671

Thermal

Low temperature flex @ -55ºC No cracking during mandrel bend ASTM D 2671

12

Flammability 30 s (max) ASTM D 635

Electrical Electric strength 8 MV/m (min) IEC 243

13

Water absorption - 0.5% (max) ISO 62

Tensile strength 11 MPa (min) ISO 1817

Aviation fuel F40

Ultimate elongation 200% (min) after immersion for 24 hrs @ 23ºC

14

Tensile strength 11 MPa (min) ISO 1817

Fluid resistance Lubricating oil O-149

Ultimate elongation 200% (min) after immersion for 24 hrs @ 23ºC

15

Tensile strength 11 MPa (min) ISO 1817

Hydraulic fluid H515

Ultimate elongation 200% (min) after immersion for 24 hrs @ 23ºC

16

17

18

www.is-rayfast.com 223