Page 487 - IS-Rayfast Catalogue - Issue 9, 2017

P. 487

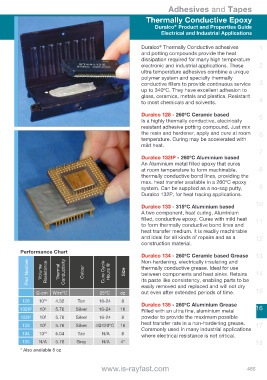

Adhesives and Tapes

Thermally Conductive Epoxy

Duralco Product and Properties Guide

®

Electrical and Industrial Applications

Duralco Thermally Conductive adhesives 1

®

and potting compounds provide the heat

dissipation required for many high temperature

electronic and industrial applications. These 2

ultra temperature adhesives combine a unique

polymer system and specially thermally

conductive fillers to provide continuous service 3

up to 340ºC. They have excellent adhesion to

glass, ceramics, metals and plastics. Resistant

4

to most chemicals and solvents.

Duralco 128 - 260ºC Ceramic based 5

Is a highly thermally conductive, electrically

resistant adhesive potting compound. Just mix

the resin and hardener, apply and cure at room 6

temperature. Curing may be accelerated with

mild heat.

7

Duralco 132IP - 260ºC Aluminium based

An Aluminium metal filled epoxy that cures

at room temperature to form machinable, 8

thermally conductive bond lines, providing the

max. heat transfer available in a 260ºC epoxy

system. Can be supplied as a no-sag putty, 9

Duralco 132P, for heat tracing applications.

10

Duralco 133 - 315ºC Aluminium based

A two component, heat curing, Aluminium

filled, conductive epoxy. Cures with mild heat

11

to form thermally conductive bond lines and

heat transfer medium. It is readily machinable

and ideal for all kinds of repairs and as a 12

construction material.

Performance Chart

Duralco 134 - 260ºC Ceramic based Grease 13

Part Number Volume Resistance Thermal Conductivity Colour Cure Cycle Hours @ Size thermally conductive grease. Ideal for use 14

Non-hardening, electrically insulating and

between components and heat sinks. Retains

its paste like consistency, enabling parts to be

easily removed and replaced and will not dry

Ω-cm W/mºC 25ºC oz out even after extended periods of time. 15

128 10 16 4.32 Tan 16-24 8

Duralco 135 - 260ºC Aluminium Grease

132IP 10 5 5.76 Silver 16-24 16 16

Filled with an ultra fine, aluminium metal

132P 10 5 5.76 Silver 16-24 8 powder to provide the maximum possible

heat transfer rate in a non-hardening grease.

133 10 5 5.76 Silver 4@120ºC 16 17

Commonly used in many industrial applications

134 10 16 5.04 Tan N/A 8

where electrical resistance is not critical.

135 N/A 5.76 Grey N/A 4* 18

* Also available 8 oz

www.is-rayfast.com 485