Page 273 - IS-Rayfast Catalogue - Issue 9, 2017

P. 273

Terminals and Splices

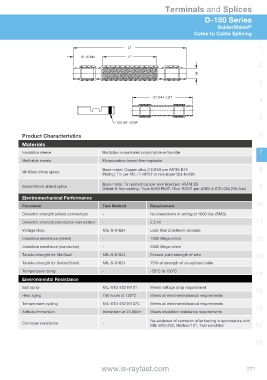

D-150 Series

SolderShield ®

Cable to Cable Splicing

L1 1

10.16 Min. L2

2

ID

3

4

5

Product Characteristics 6

Materials

Insulation sleeve Radiation crosslinked polyvinylidene fluoride 7

Melt-able inserts Fluorocarbon based thermoplastic

Base metal: Copper alloy C10200 per ASTM B75 8

MiniSeal crimp splice

Plating: Tin per MIL-T-10727 or nickel per QQ-N-290

Base metal: Tin-plated copper wire braid per ASTM B3

SolderShield shield splice 9

Solder & flux coating: Type Sn63 Pb37. Flux: ROM1 per ANSI-J-STD-004 (RA flux)

Electromechanical Performance

10

Parameter Test Method Requirement

Dielectric strength (shield connection) - No breakdown or arcing at 1000 Vac (RMS)

Dielectric strength (conductor connection) - 2.5 kV 11

Voltage drop MIL-S-81824 Less than 2 millivolt increase

Insulation resistance (shield) - 1000 Mega-ohms 12

Insulation resistance (conductor) - 5000 Mega-ohms

Tensile strength for MiniSeal MIL-S-81824 Exceed yield strength of wire 13

Tensile strength for SolderShield MIL-S-81824 75% of strength of un-spliced cable

Temperature rating - -55ºC to 150ºC

14

Environmental Resistance

Salt spray MIL-STD-202 M101 Meets voltage drop requirement

15

Heat aging 750 hours at 150ºC Meets all electromechanical requirements

Temperature cycling MIL-STD-202 M107C Meets all electromechanical requirements

16

Altitude immersion Immersion at 22,860m Meets insulation resistance requirements

No evidence of corrosion after testing in accordance with

Corrosion resistance -

MIL-STD-202, Method 101, Test condition 17

18

www.is-rayfast.com 271